- Introduction

- What is Discontinuity?

- Types of Discontinuities

- Causes of Discontinuity in Electronic Circuits

- Component Failure

- Poor Connection

- Circuit Board Issues

- External Interference

- Detecting Discontinuities with Oscilloscopes

- 1. Connect the Oscilloscope

- 2. Set Appropriate Time and Voltage Scales

- 3. Identify Anomalies

- 4. Use Advanced Features

- Summary of Discontinuity Types and Their Impacts

- Conclusion

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

Imagine you're closely observing an electronic signal and, out of nowhere, it changes dramatically. This abrupt alteration is more than just a hiccup in your readings. Discontinuity can signal underlying issues in electronic circuits, impacting their performance and reliability.

In this article, we will discuss the science behind discontinuity to understand its implications and how it shapes the approach to electronic troubleshooting and design.

What is Discontinuity?

Discontinuity in electronics refers to an abrupt change in the characteristics of a signal within a circuit. These changes can be in voltage, current, or any other electrical property. Discontinuities are often unintended and can indicate problems in the circuit.

Types of Discontinuities

- Voltage: a sudden change in voltage level.

- Current: an abrupt change in current flow.

- Impedance: a rapid shift in impedance values within a circuit.

| Key Takeaway |

| Understanding and effectively managing discontinuities in electronic circuits is crucial for maintaining the integrity and performance of electronic systems, requiring a combination of keen observation and a thorough knowledge of circuit behavior. |

Browse Our Selection of Used Oscilloscopes

Causes of Discontinuity in Electronic Circuits

Discontinuity in electronic signals can stem from various sources. Understanding these causes is essential for diagnosing and resolving issues effectively. Let's delve deeper into each of the four primary causes.

Component Failure

- How it happens: Electronic components such as resistors, capacitors, and inductors can fail due to age, overheating, or manufacturing defects. For instance, a capacitor might leak its electrolyte over time, or a resistor could burn out due to excessive current.

- Impact: The failure of these components can disrupt the normal flow of current or alter the expected behavior of the circuit, leading to discontinuities in the signal that are often erratic and unpredictable.

- Detection and resolution: Regular inspection and testing of components using multimeters or specialized test equipment can identify faulty parts. Replacing these components usually restores the circuit's functionality.

Poor Connection

- How it happens: Connections in a circuit can become loose, or oxidized over time, especially in environments with high humidity or temperature fluctuations. Connector pins, solder joints, and wire terminals are common sites for such issues.

- Impact: These poor connections can lead to intermittent contacts, where the connection is momentarily lost and then reestablished, causing sudden changes or drops in the signal.

- Detection and resolution: Visual inspection, along with wiggle tests (gently moving wires and connectors to see if the signal fluctuates), can help locate loose connections. Cleaning, re-soldering, or tightening the connections can often fix the issue.

Circuit Board Issues

- How it happens: Printed Circuit Boards (PCBs) can suffer from various physical issues like cracked traces, which are the pathways for electrical signals, or cold solder joints, which occur when solder does not properly melt and bond with the component leads and the PCB.

- Impact: These physical defects can interrupt the flow of electricity, leading to discontinuities. For example, a cracked trace might open the circuit intermittently, depending on the board's flexing or temperature changes.

- Detection and resolution: A thorough visual inspection under magnification, coupled with techniques like continuity testing, can identify these issues. Repairing PCBs often involves re-soldering or bridging broken traces with jumper wires.

External Interference

- How it happens: Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are disturbances caused by external sources like motors, transformers, radio transmitters, or even nearby electronic devices. These interferences can be picked up by circuit components or wiring, especially if the circuit lacks proper shielding.

- Impact: EMI and RFI can superimpose unwanted signals onto the circuit’s normal operation, leading to erratic signal behavior and discontinuities.

- Detection and resolution: Identifying EMI or RFI often involves checking for correlations between the interference and the operation of other equipment. Solutions might include adding shielding to the circuit, using filters, improving grounding, or re-routing signal paths away from sources of interference.

Diagnosing and fixing discontinuities in electronic circuits requires a methodical approach.

It involves careful inspection, testing, and understanding of how various factors like component health, connection quality, PCB integrity, and external factors contribute to these issues.

Addressing the root cause not only resolves immediate problems but also enhances the overall reliability and performance of the electronic systems.

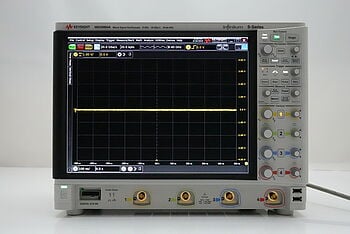

Detecting Discontinuities with Oscilloscopes

Oscilloscopes are vital tools for electrical engineers and technicians to detect and analyze discontinuities in electronic signals. Their ability to visualize electrical signals in real-time makes them ideal for pinpointing issues that could lead to signal integrity problems.

Let’s expand on the steps involved in using an oscilloscope to detect discontinuities.

1. Connect the Oscilloscope

- Proper connection: Ensure that the oscilloscope probes are correctly connected to the circuit. This involves attaching the ground clip to a common ground point and the probe tip to the test point in the circuit.

- Probe calibration: Before measurements, calibrate the probes to ensure accurate readings. This typically involves adjusting the compensation capacitor on the probe to match the oscilloscope's input impedance.

- Safety considerations: Always adhere to safety protocols, particularly when working with high voltages, to prevent damage to the oscilloscope and to ensure user safety.

2. Set Appropriate Time and Voltage Scales

- Time base adjustment: To observe the waveform’s behavior over time, it is crucial to set the correct time base (time per division). This allows you to capture fast transients or observe slower signal variations.

- Voltage scaling: Adjust the vertical scale (volts per division) to suit the signal amplitude. Proper scaling ensures that the waveform uses the full screen height without clipping, providing a detailed view of the signal.

- Fine tuning: Use fine adjustments for precise scaling, especially when looking for small anomalies in a largely stable signal.

3. Identify Anomalies

- Waveform analysis: Scrutinize the waveform for any irregularities, such as spikes, dropouts, or unexpected fluctuations. Discontinuities often manifest as abrupt changes in the waveform.

- Pattern recognition: Look for repeating patterns or irregularities that might indicate intermittent issues, which are often the hardest to diagnose.

- Comparative analysis: If possible, compare the questionable signal to a known good waveform, which can highlight deviations indicative of discontinuities.

4. Use Advanced Features

- Cursors: Utilize on-screen cursors to measure the time and voltage differences precisely. This is particularly useful for quantifying the extent of discontinuities.

- FFT analysis (Fast Fourier Transform): This feature transforms the time-domain signal into its frequency components. It's invaluable for identifying noise or interference of specific frequencies that could be causing the discontinuity.

- Triggering options: Advanced triggering options can help isolate specific events within a signal, making it easier to observe and analyze transient phenomena that may be causing discontinuities.

- Storage and analysis: Modern oscilloscopes allow you to store waveforms for later analysis, a feature that can be crucial when dealing with intermittent issues that require extended monitoring.

Using an oscilloscope effectively to detect discontinuities requires not only a thorough understanding of the tool but also a keen eye for detail in waveform analysis.

As discontinuities can be subtle or intermittent, a methodical approach, combined with the oscilloscope's advanced capabilities, is key to the successful diagnosis and resolution of these issues.

Empower Your Projects With a Used Keysight Oscilloscope

Summary of Discontinuity Types and Their Impacts

| Type of Discontinuity | Possible Causes | Impact on Circuit |

|---|---|---|

| Voltage | Component failure, poor connections | Unstable power supply, erratic behavior |

| Current | Broken traces, faulty components | Overheating, potential component damage |

| Impedance | Mismatched components, design flaws | Reflections, signal loss |

Understanding discontinuity in electronics is not just about identifying a problem; it's about preserving the integrity and efficiency of the entire electronic system.

Whether you're troubleshooting a complex circuit or ensuring the smooth operation of a simple device, a keen awareness of discontinuity and its implications is a valuable asset in the field of electrical engineering.

Conclusion

Discontinuity in electronic signals can be a revealing indicator of underlying issues in a circuit. Understanding how to detect and address discontinuities is essential to ensure the performance, reliability, and longevity of electronic systems.

The quality and capabilities of the equipment you use can significantly influence the efficiency and accuracy of your diagnostics.

Equip yourself with the best tools without breaking the bank with the Keysight Used Equipment Store. Here, you can find a wide range of premium used oscilloscopes, spectrum analyzers, waveform generators, multimeters and more.

Each piece of equipment is rigorously tested and verified, ensuring that you receive reliable, high-quality tools that meet your professional needs. Visit the Keysight Used Equipment Store today and equip yourself with the tools you need to expertly navigate the complex world of electronic discontinuities.

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our Premium Used Oscilloscopes.

- Call tech support US: +1 800 829-4444

Press #, then 2. Hours: 7 am – 5 pm MT, Mon– Fri - Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists.

- Talk to your account manager about your specific needs.