- introduction

- What is Power Factor?

- Understanding Power Factor: The Beer Analogy

- Optimize Your Power Factor with Precision: Discover Keysight's Refurbished Solutions

- Power Factor Formula

- Factors Affecting Power Factor

- How to Calculate Power Factor

- Leading vs. Lagging Power Factor

- How to Measure and Monitor Power Factor

- Poor Power Factor Correction

- ROI of Power Factor Correction Measures

- The Importance of Power Factor

- Trust Keysight's Calibrated Equipment for Your Electrical Needs

- Conclusion: Elevate Your Electrical Efficiency with Strategic Power Factor Management

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

Ever felt like tackling power factor in your electrical systems is like trying to solve a puzzle without all the pieces? It's frustrating, especially when you're aiming for those big efficiency and sustainability goals.

Whether you're at home trying to shave a bit off your electricity bill, running a business with an eye on sustainability, or an engineer fine-tuning systems, understanding power factor is a game-changer. It's the key to not just meeting but beating those energy efficiency targets.

So, let's break it down, simplify the formula, and get you to a place where you're confident in making your systems as efficient as they can be. No more guessing, just clear, straightforward steps towards greener, more reliable operations.

What is Power Factor?

Imagine your electrical system is like a vehicle, and power factor measures how efficiently this "vehicle" uses its "fuel" – the electricity.

Essentially, power factor is a measure of how well an electrical system converts electric power into useful work output.

It's like comparing cars based on their fuel efficiency. A high power factor means your system is like a fuel-efficient car, using most of the electricity it draws to do the work it's supposed to, with minimal waste.

A high power factor equals high electrical efficiency, and here's why:

- Less waste: Just like a car that gets more miles per gallon, a system with a high power factor uses the majority of its electrical "fuel" effectively, with little going to waste.

- Cost savings: High efficiency means you're getting more bang for your buck. You're paying for electricity that's actually being used productively, rather than paying for power that doesn't contribute to the work output.

So, aiming for a high power factor is like aiming for a car with the best MPG – it's all about maximizing efficiency and reducing waste.

Understanding Power Factor: The Beer Analogy

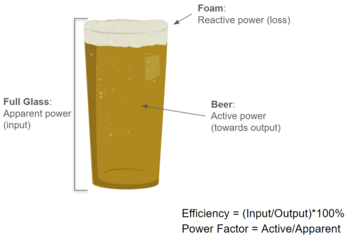

Understanding the concept of power factor might initially seem confusing, but let's simplify it using something many can relate to: a pint of beer.

In this analogy, the total power in your electrical system is represented by a full pint of beer. However, not all of it is beer; some of it is just foam.

- Total power (apparent power): This is the full pint, combining both the beer and the foam. In electrical terms, this is known as apparent power, measured in volt-amperes (VA), representing the total power supplied to your system.

- Useful power (active or real power): The beer itself symbolizes the active or real power, measured in watts (W). This is the power that actually does work, such as lighting up a room or powering machinery.

- Wasted power (reactive power): The foam on top represents reactive power, measured in reactive volt-amperes (VAR). It's necessary for the functioning of some electrical components (like motors and transformers) but doesn't directly contribute to useful work output.

The goal in electrical efficiency, similar to enjoying a pint, is to maximize the "beer" (useful power) and minimize the "foam" (wasted power).

- Power factor: This is the ratio of active power to apparent power. A high power factor means you have more beer and less foam, signifying a more efficient electrical system.

Understanding these components helps us grasp why a high power factor is desirable:

- Maximizing efficiency: By increasing the proportion of useful power, you're ensuring that more of the total power supplied is used effectively.

- Reducing waste: Minimizing reactive power means less energy is wasted, leading to cost savings and more sustainable operations.

In essence, achieving a high power factor is about ensuring that when you're paying for a pint, you're getting as much beer and as little foam as possible.

Optimize Your Power Factor with Precision: Discover Keysight's Refurbished Solutions

Power Factor Formula

The power factor formula is a simple yet powerful tool for understanding how efficiently an electrical system is operating.

It's calculated as the ratio of active power (P) to apparent power (S), expressed as PF= P/S.

In this formula, P (active or real power) is measured in watts (W), and S (apparent power) is measured in volt-amperes (VA).

Significance in Practical Terms

- Efficiency measurement: This formula directly measures the efficiency of an electrical system. A power factor closer to 1 (or 100%) means that most of the power is being used effectively for work, with minimal waste. Conversely, a lower power factor indicates inefficiency, with a larger portion of the power not doing useful work.

- Cost implications: Utilities often charge higher rates for lower power factors because they have to generate more apparent power (S) to ensure that the required active power (P) is delivered. Improving the power factor can thus lead to significant cost savings on electricity bills.

Relating Back to the Beer Analogy

Using the beer analogy, the power factor formula tells us how much of our pint is beer (useful power) versus foam (wasted power). If we consider:

- Active power (P) as the beer: The part of the power that actually does work (lights our homes, runs our appliances).

- Apparent power (S) as the full pint (beer + foam): The total power supplied to the system.

A high power factor indicates you're getting a pint mostly full of beer with very little foam on top, meaning you're efficiently using the power you're paying for. In contrast, a low power factor is like paying for a pint that's half foam—inefficient and wasteful.

Understanding and applying the power factor formula allows individuals and businesses to assess and improve their electrical systems' efficiency, much like choosing the best pint of beer for your money.

A power factor calculator is a practical tool for allowing you to calculate energy use, optimizing operations, and ultimately, saving costs while contributing to more sustainable energy consumption.

Power Triangle

- A power triangle helps visualize the relationship between:

- Active power (P – the beer)

- Reactive power (Q – the foam, which doesn't do useful work but is necessary for some equipment to operate)

- Apparent power (S – the full glass)

In our analogy, if you think of the beer as the "real" work being done (active power), the foam (reactive power) doesn't help quench your thirst but is a part of the experience. The longer side of the triangle (apparent power) shows you the total "experience" of your pint – both beer and foam combined.

Understanding this triangle is crucial because it shows you not just how much power you're using efficiently, but also how much is being wasted or not utilized as well as it could be.

By aiming to reduce the foam (minimize reactive power) and increase the beer (maximize active power), you improve your power factor, meaning more of your electrical system's energy is doing useful work.

And just like getting the perfect pint with less foam, optimizing your power factor leads to a more efficient, cost-effective, and environmentally friendly electrical system.

Factors Affecting Power Factor

Several factors can influence the power factor in electrical systems, impacting their efficiency and operational cost. Understanding these factors is crucial for optimizing power use and achieving more sustainable energy consumption.

- Type of load (inductive or capacitive): Electrical loads can be broadly categorized into inductive (e.g., motors, transformers) and capacitive (e.g., capacitor banks). Inductive loads tend to lower the power factor because they require reactive power for creating magnetic fields, leading to a phase difference between voltage and current. Capacitive loads, on the other hand, can improve the power factor by supplying reactive power to the system, reducing the need for it to be supplied by the source.

- Distribution of loads: The way loads are distributed across an electrical system also affects its power factor. A system with a mix of inductive and capacitive loads might have a more balanced power factor, while a system heavily skewed towards inductive loads might suffer from a lower power factor. Varied load conditions, including partial loads, can also impact the power factor unfavorably.

- Harmonics: Harmonics are a form of electrical pollution that distorts the wave shape of the electrical current. They are generated by non-linear loads such as variable-speed drives, compact fluorescent lights, and computers. Harmonics can significantly degrade the power factor and the overall efficiency of electrical systems. They cause additional heat in the system, leading to energy losses and potentially damaging equipment. The presence of harmonics complicates the measurement and correction of the power factor, requiring specialized filtering equipment to mitigate their effects.

A less-than-ideal power factor signifies that a significant portion of the electrical power is being wasted as reactive power or lost due to harmonics, which not only increases energy costs but also puts a strain on the electrical infrastructure.

It can lead to increased demand charges on utility bills, reduced capacity for carrying useful power, and heightened risk of equipment overheating and failure.

Understanding these factors is the first step towards optimizing the power factor. By addressing issues like load imbalance, excessive inductive loads, and harmonics, engineers can improve their electrical system's efficiency, reduce energy consumption, and save on operational costs.

How to Calculate Power Factor

Calculating the power factor is a straightforward process that involves measuring two key components of your electrical system: active power and apparent power.

Here’s a step-by-step guide to help you through the calculation, including examples to illustrate how it works in different scenarios.

- Measure active power (P): Active power is the actual power consumed by the electrical devices to perform work. It is measured in watts (W). Use a power meter to accurately measure this value in your system.

- Measure apparent power (S): Apparent power is the combination of active power and reactive power in the system, measured in volt-amperes (VA). This can also be measured directly with a power meter or calculated as S=V×I, where V is the voltage and I is the current.

- Calculate power factor (PF): The power factor is the ratio of active power to apparent power, expressed as PF= P/S.

Example 1: Residential System

Suppose a household has an active power consumption of 3,000 watts and an apparent power of 3,750 VA. The power factor would be PF= 3000/3750 =0.8 or 80%.

Example 2: Industrial System

An industrial motor operates with an active power of 15,000 watts and an apparent power of 18,750 VA. Thus, PF= 15000/18750 =0.8, indicating a power factor of 80%.

Accurate measurement of active and apparent power is crucial for precise calculations. A high-quality power meter can provide these measurements directly, simplifying the process.

Understanding your system’s power factor is essential for identifying efficiency improvements, potentially leading to energy savings and reduced operational costs.

Leading vs. Lagging Power Factor

In electrical systems, power factor can either be leading or lagging, each indicating a different relationship between voltage and current, and influenced by the type of loads the system carries.

- Lagging power factor: This is common in systems dominated by inductive loads, such as motors and transformers. In these cases, the current lags behind the voltage because inductive loads tend to store energy in magnetic fields, which delays the current flow. A lagging power factor signifies that the system is using more reactive power, leading to inefficiencies and increased energy costs.

- Leading power factor: This occurs in systems with a significant presence of capacitive loads, like capacitor banks. Here, the current leads the voltage as capacitive loads store energy in electric fields, pushing the current ahead. A leading power factor can indicate an overcompensation for reactive power, which, while less common, can also cause inefficiencies in power distribution.

The effects of leading and lagging power factors on electrical systems are crucial in devising power factor correction strategies.

Systems with a lagging power factor may employ capacitors to reduce reactive power demand, thereby improving efficiency. Conversely, systems with a leading power factor might need to balance with inductive loads to optimize performance.

Here's a table comparing the characteristics, causes, and effects of leading versus lagging power factors:

| Characteristic | Leading Power Factor | Lagging Power Factor |

|---|---|---|

| Causes | Predominance of capacitive loads. | Predominance of inductive loads. |

| Effects on System | Can indicate overcompensation, potentially causing voltage regulation issues. | Leads to inefficiencies, increased energy costs, and strain on the system. |

| Correction Strategy | Introduce inductive loads to balance. | Add capacitive loads to reduce reactive power demand. |

Understanding whether a power factor is leading or lagging helps in effectively managing and correcting it, ensuring electrical systems operate more efficiently and economically.

How to Measure and Monitor Power Factor

Measuring and monitoring power factor is essential for maintaining an efficient and cost-effective electrical system. With the right tools and methods, you can ensure your system operates at its best, reducing waste and saving on energy costs.

Here are some effective ways to measure and monitor power factor:

- Power analyzers: These sophisticated devices are capable of measuring a wide range of parameters, including power factor, active power, reactive power, and harmonics. They provide detailed insights into the electrical system's performance, helping identify inefficiencies and areas for improvement.

- Smart meters: Modern smart meters go beyond traditional metering by offering detailed information about power usage, including power factor. They can communicate data in real-time, allowing for continuous monitoring and better energy management strategies.

- Clamp meters and multimeters: For quick checks or troubleshooting, clamp meters and multimeters with power measurement capabilities can be used to measure power factor directly at various points in the system.

Top-Tier Tools

Recognized for their accuracy and reliability, Keysight offers premium tools for measuring and monitoring power factor.

Our power analyzers provide comprehensive analysis capabilities, while our smart meters and multimeters offer user-friendly interfaces for ongoing monitoring, making them vital for professionals seeking to optimize electrical systems.

Using these tools and methods, businesses and homeowners can take proactive steps to enhance their electrical systems. This will not only promote efficiency and sustainability but also effectively manage operational costs.

"Customers come to us and buy used, because they get premium Keysight quality with a lower price and we ship within 2 weeks.” – Keysight Account Manager

Poor Power Factor Correction

Power factor correction (PFC) is essential for improving the efficiency of electrical systems, reducing energy costs, and minimizing the carbon footprint of operations.

Here's a look at common PFC methods, their applications, challenges, and the return on investment (ROI) businesses can expect.

Common Power Factor Correction Methods

- Capacitors: Capacitors are used to counteract the lagging power factor caused by inductive loads. They store and release electrical energy, thus providing reactive power locally and reducing the demand from the supply.

- Inductors: Less common, inductors are used for correcting a leading power factor, which is rare in most commercial and industrial settings.

- Synchronous condensers: These are essentially large synchronous motors that, when operated at no load, can supply or absorb reactive power, thus adjusting the power factor as needed.

- Software-controlled PFC devices: Modern solutions incorporate software for dynamic power factor correction, adjusting to the system's needs in real-time and optimizing efficiency.

Challenges and Considerations

Implementing PFC measures requires an upfront investment and a clear understanding of the system's needs.

Over-correction can lead to a leading power factor, potentially causing other efficiency and reliability issues. Additionally, the presence of harmonics in the system can affect the performance of PFC devices, necessitating harmonic filters or specialized PFC equipment.

ROI of Power Factor Correction Measures

| Cost Factor | Without PFC | With PFC |

|---|---|---|

| Energy Cost | Higher due to inefficiencies | Reduced |

| Equipment Stress | More frequent maintenance | Less wear |

| Utility Charges | Higher peak demand charges | Lower charges |

High-Quality Equipment

Using high-quality, refurbished and accurately calibrated equipment for PFC, such as those available from Keysight's premium used store, can significantly enhance the effectiveness and reliability of power factor improvement measures.

Equipment from a reputable provider ensures that businesses not only meet their efficiency goals but also maximize the ROI of their PFC strategies:

The Importance of Power Factor

Optimizing power factor is crucial for both environmental sustainability and economic efficiency. A high power factor indicates that an electrical system is using its power supply effectively, minimizing waste and reducing the carbon footprint of operations.

Economically, it translates to lower energy costs and enhanced operational efficiency.

How Power Factor Affects Utility Billing

Utility companies often charge commercial and industrial customers based on both their energy consumption and their power factor.

A low power factor leads to higher utility bills due to:

- Increased demand charges

- Penalties for maintaining a power factor below a specified threshold, typically around 0.9 or 90%

Tips for Businesses to Improve Power Factor

- Install capacitors: Placing capacitors at strategic points in your electrical system can correct a lagging power factor by supplying reactive power where it's needed.

- Maintain equipment: Regular maintenance of motors and other inductive equipment can help prevent their efficiency from degrading, which in turn helps maintain a healthier power factor.

- Upgrade to high-efficiency motors: These motors have a higher power factor compared to standard motors, reducing the need for additional correction.

- Monitor power quality: Use power quality analyzers to identify and address issues that may be affecting your power factor, such as harmonics.

- Consider power factor correction equipment: For systems with variable loads, dynamic power factor correction equipment can adjust in real-time to changes, maintaining optimal power factor.

Trust Keysight's Calibrated Equipment for Your Electrical Needs

Conclusion: Elevate Your Electrical Efficiency with Strategic Power Factor Management

In this article, we've discussed why power factor is important for making your electrical system as efficient and green as possible. We started with the basics, showing you how to figure out your power factor, and then we moved on to how fixing it can save you money and help the environment.

We've analyzed different ways to improve your power factor, from using simple tools like capacitors to more advanced tech like synchronous condensers. And we've seen how using high-quality, reliable equipment can make a big difference in getting your power factor right.

Now it's over to you. Take a look at your own electrical systems and think about the changes you might need to make. There's a lot you can do to boost your efficiency, cut down on costs, and do your bit for the environment.

Remember, getting your power factor in shape is more than just a technical fix. It's about taking charge of how much energy you use and making smart choices that are good for both your wallet and the world around you.

So, go ahead and unlock the full potential of your electrical setup by getting on top of your power factor management. With the right approach, you're ready to make your systems more efficient than ever.

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our premium used network analyzers, oscilloscopes, signal analyzers and waveform generators.

- Call tech support US: 1 800 829-4444

Press #, then 2. Hours: 7am – 5pm MT, Mon– Fri - Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists

- Talk to your account manager about your specific needs